I had a ton of shit to do this weekend (spoiler alert, none of it got done).

I was (as usual) behind the eight ball. Winter held on, clinging to the bitter end. It deviously gave up the exact millisecond my lawn was primed to go nuclear. This is normal; every spring my lawn goes from frozen tundra to wet burgeoning jungle in a flash.

I made a special trip to town to get fresh gas because I just knew the EPA mandated soup in my lawnmower’s tank would be crap. Then I maneuvered my truck close to the shed where the lawnmower lives because I’d need a jumpstart. Sometimes I pull the battery and keep it on a maintainer in the garage (with mixed success). This winter I left it in situ. It would certainly be dead.

Shockingly, it fired right up! No need for new gas or jumper cables? I practically fell off the seat.

The gas seemed OK too! Apparently, I had used Sta-Bil last fall? Also, the battery is made of magic?

More miracles followed! I checked under the hood and found a piece of tape stuck to it the engine with my very own writing. I’d changed the oil in September. No shit!

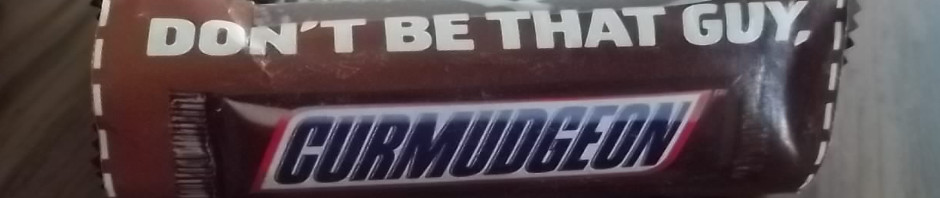

My only explanation is that some doppelgänger slipped onto my property last fall, properly “put to bed” my lawnmower, and then vanished. I ought to buy that guy a beer.

The only issue was a flat tire. Pretty good news! I limped it to the air compressor, filled it, and it held air. Could it be I would actually get to mow lawn? Usually I have to move heaven and earth every spring to resurrect various frozen equipment. I was delighted with my good fortune.

I lined up on the first strip of scraggly lawn and hit the PTO switch… nothing. I looked at the mower deck. There was no belt at all. Da fuck?!?!

I racked my brains and gradually remembered what happened. The belt broke in autumn. Being the kind of guy who’d rather build a boat than fret about landscaping, I just said “fuck it” and ended the lawnmowing season. How that led to good gas, clean oil, and a non-dead battery is a mystery.

I dimly remembered buying a belt and… holy shit… there it was! Hanging on a hook, in my shop, totally pristine and waiting… a new mower belt. Did I do that?

OK folks, you gotta’ tell me the truth here. Am I the only one who has so many irons in the fire he can’t even remember the tasks he’s accomplished? How does this work for other people?

Also, how come everyone has time to watch a gazillion hours of Game of Thrones? (On reflection I’ve never watched Game of Thrones but I did spend a few hours reading the first few books. They were OK at the start. Then it dawned on me it wasn’t going to get better. “Wait a minute, these dumbasses are never going to prepare for winter! They’re starting wars when they need to be harvesting crops. Fuck them! I have no sympathy for a single one of these nitwits. Ant and grasshopper dammit!” That’s when I stopped reading. Anyone who starts a war on the cusp of winter deserves to get Napoleoned.)

But I digress.

Back in the shop I manfully attacked the mower deck. Changing a belt should be no big deal. Emphasis on “should”.

Unfortunately, my deck was engineered by brain damaged howler monkeys; cretinous dipshits who shouldn’t have been let out of engineering class. We ought to keep overeducated wretches away from the machinery I use in real life. (Possibly, lock them in endless calculus classes until the student loans kill ‘em?) I live in a world engineered to be built in China and thrown away in America; getting shit done seems irrelevant to all parts of the flow chart!

God forbid the deck have more that one belt. That might increase friction by 0.001% and require 1/32” more metal in a few strategic places on a deck that’s carefully designed to be as flimsy as cardboard. Instead, some brass plated egghead thought it grand to wind 6’ of v-belt through 3 blade pullies, 2 idler pullies (one with a tension spring), and the engine’s PTO pulley. Six points of inflection asymmetrically scattered around a continuous loop. It’s a fuckin’ M.C Escher illustration down there!

I tried to slip the belt around various pullies while the deck was still installed… as should be possible in any sane world. When that didn’t work, I yanked the deck. In theory this is a matter of pulling a few pins but in reality it’s a PITA. I twisted my back in ways only appropriate for some MILFy yoga instructor and not a chunky bearded dude laying on cement. (I hear the song of ibuprofen singing in my ears.)

It’s a good thing I pulled the deck though. The idler pullies had “belt guides” so close to the pullies that there was no way a belt would ever “slip over” merely by releasing the tensioning spring. I don’t know if this is the OEM design or due to one of the (professionally installed) deck repairs. (I had the deck repaired at a dealer last spring.)

A note about lawn tractors. They’re all shit. Every fucking one of them. Even if your lawn tractor is a Name Brand XXX with turbo mow-amatic features… it’s either five grand or shit. If you do anything more than gingerly mowing a quarter acre of tabletop flat manicured greenery it’s going to implode like a child actor discovering cocaine. Virtually every riding lawnmower brand is excreted into shipping containers from nearly identical factories staffed by the same tragically underpaid peasants working with the same shitty plastics and pot metal. They’re engineered to whatever minimal price point some marketing jackwipe with a spreadsheet deemed necessary. I have a Cub Cadet with a Kawasaki engine. Hardly a bargain basement brand… and it’s shit. The deck rusted faster than I though possible (and a replacement deck is big bucks), the hydrostatic transmission loses traction at precisely the angle required to suit the most cringing, limp dicked, liability lawyer in creation, and the whole thing has the fit and finish appropriate for stoners making macaroni sculptures with hot glue. It was shit when it was made, it was shit when I bought it, and it’s double extra super shit when I’m contorted on a cement floor routing a belt through an infinite loop of suck.

Ugh! I hate shitty equipment and all of my equipment is shitty!

Eventually, because I could see no other solution, I removed both idler pullies, slipped on the belt, and reinstalled. That can’t be the right way. It’s gotta’ be modified from OEM right?

Also, I did read the manual! What makes you think that would help? The bulk of it was bitching that you shouldn’t do stupid things like use it to mix margaritas or hurl children at the rotating blades. Then there’s a section about how you should be wearing a safety vest, helmet, and titanium cup before you go anywhere near it. After that it spent more pages explaining it was made of materials known to the State of California to give ass cancer to puppies. Way in the back it briefly mentioned that it has a belt and only people with a PhD from Cub Cadet university should have access to this esoteric dark knowledge. However, it did spend three paragraphs saying that only a Cub Cadet belt will suffice and all those other brands should be banned by Federal law.

Finally, after a lot of swearing, I had it reinstalled. I lined up on the grass and hit the PTO. The blades were spinning, grass was getting cut, all was well. I drove three feet and the belt popped off a pulley somewhere. Dead in the water again.

I sat there on my tractor pondering my fate. “Well it could be worse” I though.

Then it started raining.

I can take a hint. I drove it back into it’s shed, shut it down, ran through the rain to the house, and poured a nip of bourbon. I’ll try again later.

The lawn, the mower and tomorrow will all be there later…

That’s a familiar story. We also have a cub cadet mower. Loaned to a “friend” and returned with a broken belt and fractured drive bearing (the thing that holds the blade on and connects to the belt). Of course one blade was bent beyond repair. The other looked like it had been used to chop through a forest made of #8 rebar. Complete disaster getting that thing apart and repaired. Parts are scarce and expensive. Priced like they’re made of pure unobtanium yet they look like aluminum cast in a sand mold in the backyard of a bootlegging distillery.

The operators manual barely mentions repairs beyond putting gas in it and having a certified technician perform annual maintenance. Ugh. At least the internet has parts diagrams that you can sort of use as a guide.

And now the hydrostatic transmission is leaking like the Clintons with classified documents. Of course, the recommended fix is a new transmission that costs more than the mower did. Damned near impossible to keep the thing running. And it wasn’t cheap when we bought it.

Would it be impossible for an American company to make a lawn mower that lasts more than 3 years, and have a dealer network that actually sells parts like seals and such? That would be the kind of winning I can appreciate. DJT are you listening?

That’s a familiar story. We also have a cub cadet mower. Loaned to a “friend” and returned with a broken belt and fractured drive bearing (the thing that holds the blade on and connects to the belt). Of course one blade was bent beyond repair. The other looked like it had been used to chop through a forest made of #8 rebar. Complete disaster getting that thing apart and repaired. Parts are scarce and expensive. Priced like they’re made of pure unobtanium yet they look like aluminum cast in a sand mold in the backyard of a bootlegging distillery.

The operators manual barely mentions repairs beyond putting gas in it and having a certified technician perform annual maintenance. Ugh. At least the internet has parts diagrams that you can sort of use as a guide.

And now the hydrostatic transmission is leaking like the Clintons with classified documents. Of course, the recommended fix is a new transmission that costs more than the mower did. Damned near impossible to keep the thing running. And it wasn’t cheap when we bought it.

Would it be impossible for an American company to make a lawn mower that lasts more than 3 years, and have a dealer network that actually sells parts like seals and such? That would be the kind of winning I can appreciate. DJT are you listening?

I wish I could say that I was sorry you had such a rough weekend, but based on how much I’ve just been laughing while reading this, I’m afraid it would be a lie! I love your rants…

That’s why I rant, to make people smile. Thanks for reading.

” I was delighted with my good fortune.” Always a bad sign.

I agree on all yer p.o.s. mower comments. And pretty much everything else.

I have an old-school Cub Cadet that hasn’t been touched since Dad died 13 years ago. Whaddayathink, fresh gas and a battery and I’m good to go? I vaguely remember something about “…busted in the drivetrain, not worth fixing”. Should be fun…

It might make a passable anchor….

Sometimes God speaks and it’s a wise man who listens and heeds. Well done. How was the bourbon? Bourbon and ibuprofen were made for those of us beyond the half century mark. You could always run sheep – but they come with issues that might make you want to go wrestle with the !@#$% lawnmower deck belt.

The bourbon was good.

Later, I reinstalled the belt and the @&^$)@#&^ tractor ate it. I think I’ll set the damn Cub Cadet on fire.

No one….and I mean this with all sincerity….should be allowed to design a damn thing unless and until said designer has physically held a wrench and performed both scheduled and unscheduled maintenance upon a daily use item in said field. Are you listening, Bombardier Aircraft? What kind of crack are your Learjet guys on? I want some!

One word, and I hate to say it..

SCAG.

Residential equipment is garbage. Find you a decent used commercial unit and revel in it’s user friendly serviceability.

I’ve ran a 52″ Tiger cub for the better part of 20 years. Air cooled Kow, well built and runs like a sumbitch. The motor is good for at least 3k hours, and belts, blades and BS are almost as ubiquitous as SB Chevy parts.

Any “lawn tractor” built recently is only good for .50 cal target practice.

Near as I can tell lawn maintenance machinery is kind of like that Demolition Man movie, where I missed the Great Lawnmower War and now all mowers are made by MTD. There are some really good industrial units out there (I do like my Grasshopper), but they cost more than my first car did new. I figure since they’re all the same and I have shop space, I’ll just buy the newest, cheapest I can find every few years and retire them to the parts pile as they wear out. What really cheezes me is how Briggs and Tecumseh have given me utter failures for engines, but the cheap Chinese shit at 1/4 the cost actually seems fairly reliable in comparison! This is no way to maintain customer loyalty and swapping motors isn’t rocket science. Also, since nobody but me drains gas before putting machinery away, the carb rebuild kit for the Briggs is $25 and the whole brand-new assembled carb for the Chinese motor is $12.50 from Amazon with Prime shipping. Sign me up! Carbs, to me, are kind of like women — I love what they do, I have a fair knowledge on how it’s all done, but I seem to have absolutely no ability to influence events and make it happen. Tuning a carb, to me, is luck or voodoo. Fixing a broken one is difficult, but replacing them with a newer unit is trivially easy in comparison and no longer costs a house and alimony. Until the domestics can make a motor that lasts four times as long as the Chinese, I’m replacing instead of fixing. I hate that, but the numbers insist.

– Max

Wise choice, AC.

I have a pretty-good John Deere 52″, inherited from my late father. Kohler V-twin, decent mower; however, it’s developed an electrical fault.

Now, I have a degree in electronics engineering (I will not capitalize that, it’s not worth it). I’ve done component-level electronics repair for a living. I still work in the field, peripherally, as a calibration tech. And I HATE chasing electrical faults on anything that moves under its own power.

The mower is 20+ years old, & still has all kinds of sensors, switches, & such extraneous bullshit. Fortunately, Dad, being of sound mind, jumpered most of the bullshit like the sensor which shuts the thing off if you get off the seat while it’s in gear, and other such stupid shit: if I drop a wheel into a hole going uphill, & can’t go either way, I want it running while I shove it up out of the hole. Cripples don’t do well at pushing inert mowers up hills, & I want the drive working. Even so, since I don’t know which component is the problem, I have to check each & every one until I find the fault.

To save time, I bought a $200 Murray 36″ off Craigslist to take up the slack until I have time for the big mower. Slower, bu I have other pressing matters, such as motorcycles, to occupy my time.

I wonder if the JD will ever run again. As long as I can ride a bike, on the rare occasions I have time to ride, I’m not sure I care.

Best of luck to you.

Last winter I bought a older used JD150LT, paid $80. It took another $50 in parts and about 30 hours of my labor were needed to get it in working condition.

It took drilling holes in the wheels so I could get a puller hooks to hold so I could exert force, heat from a torch, can of PB Blaster and many, many hits from a twelve pound sledge to get the wheels off.

If I ever find the person that decided that the rear wheels only needed rust to hold the wheels to the shaft I will weld their cars lug nuts to the lugs. Then slice their tires valve stems.

An excellent rant. I laughed, and recalled all the ungood times.

It’s only a matter of time until the current unit fries a belt or something, and there but for the grace of God go I.

Budd:

“I HATE chasing electrical faults on anything that moves under its own power”

Builds character.

As a vet, though, y’all probably already have more than enough character :-).

At my age I often find that I have done THE RIGHT THING ( Like buying the belt) but forgot that I did it. Not quite sure what the lesson is here but I intend to keep trying to accomplish it.

One of your previous missives came to mind on Saturday. The one about F-it money and F-you money.

The 3rd Amazon hydrostatic belt in a year shredded on my 20 year old Simplicity Zero Turn. Faced with working in a 95 degree driveway with dirt falling on my face I’m dangerously close to spending some F-it money.

I’m trying hard to pick the right value to price point. Too much data; Briggs, Kohler or Kawa6? Stamped deck or fabbed deck? But once, cry once? Or continue being a cheap dick? SMH

I’m in the same boat. My mower has pissed me off and I’m willing to hurl money at it. But I have no idea the right price point to buy something that won’t collapse in a few years. Good luck.

The middle ground won out. The John Deere with a Briggs just felt too homeownerish, and I didn’t want to go full commercial landscape quality.

Ended up with a Hustler with a 23 horse Kawasaki. (Upper end homeowner or low end commercial?)

I’m going to go ape and buy a compact tractor. Too much drama just doing homestead chores… I need “runs and doesn’t need babysitting” equipment. Don’t have it yet, (I’m allergic to payments) but the time grows nigh. When I die I want to be buried in whatever machine I finance (I’ll probably still be making payments anyway).

Compact tractors are super helpful. I we have a 33 HP new holland for use around the homestead. The front end forks and grapple are real back savers. Spend the extra money and get a front end loader with the third function valve. It gives you options for tools later. Westendorf brand has been reliable.

Sadly we don’t have a belly mower for finish cutting the lawn. Just a brush mower for the rest of the place. Belly mower is on our wish list, along with a box scraper to maintain the gravel road we call a driveway.

I’m shopping for a compact tractor in the 35 hp range. I’m going to hitch a 3pt finish mower and use it on my lawn. Then I can throw my Cub Cadet riding lawnmower in a lake!

I agree that the loader is key. I’m not sure I can afford the scratch for a third valve though. (Wish I could.) I’m more interested in a cab and I can’t afford both. Heat will be a big game changer. I’m sick of freezing my ass off all winter. I hope a snowbucket on a 35 hp is a good way to move snow.

Any opinions on a Kioti?

Ah. A cab. Now there’s something to be proud of. The object of every mans desire when the temps dip below freezing and the insulated bib overalls just don’t get it done. It’s one thing I line away for when it’s cold outside. Sadly life is a series of compromises and concessions.

It’s a toss up between 3d valve grapple and a cab. In the spring (when I bought the 3d valve kit), lift was more important than warmth. Every winter I whine about an no shelter from the wind. Thank goodness for hot coffee and a big fireplace.

35 HP with a good blade should push show pretty well. I use a drag blade on the 3 point and push it in reverse to clear a path for the cars.

I have no experience with Kioti brand equipment. I do have some experience with Korean skid loaders. They rock! Wish I could come up with the scratch to get a skid loader and mini excavator. Those are serious tools. I suspect you will be happy with a tractor made in Daegu. It’s a coastal town (city) fuels by factories that make heavy construction equipment, small ocean going ships (the big ships are built near Incheon), and entertaining itinerant tourists and sailors on their way to the southern island resorts. Did I mention that I’ve spent 8 years in ROK at the behest of our federal masters of the universe. Korea one or two years at a time, between all expense paid trips to the paradise lands of Mohammedans.

Around here it’s John Deere for the big farms, Ford/New Holland for the small homesteads. Kubota and Mahindra are making serious inroads in the compact equipment arena; both have serious dealer networks for repair parts.

Parts availability is the big selling point for me. How many dealers are within a 90 minute drive would be a deciding factor in what equipment to buy.

Right now out local implement sellers are offering low (relatively) interest rates on new equipment. Probably the same nation wide. Not that I buy brand new equipment. I’m always skulking around the lease returns looking for low hours. Hah. Good luck with that, says my supportive but skeptical and long suffering bride.

I decided a heated cab is worth whatever it’s going to cost. I got nailed with bronchitis two winters in a row and don’t want a third. You know the saying:

“Once is happenstance. Twice is coincidence. Three times is enemy action” ― Ian Fleming

I’m going to nip enemy action in the bud! Especially after last February which was just about the worst winter I’ve experienced. That said, I sure hope those cabs are warm because I haven’t yet proven it. Of course, tractor salesmen insist I’ll roast while moving snow in -30 blizzards and stay cool even if I’m driving across the Sahara but I see lots of Plexiglas and not much insulation. I have my doubts. On the other hand, nothing can be worse than no protection at all – which has been my lot for decades. There will be a full report when winter comes again.

If the days of man are indeed three-score and 10; this is my last mower purchase and I intend to enjoy it.