[This post has no politics. We all need a break.]

Last year, when practicality won out over my stubborn refusal to take on payments, I bought a new tractor. It has a bucket. The bucket is a bit small for carrying firewood. I wanted to carry larger amounts so I bought a “carryall”.

A carryall is a cheap and supremely crude three point hitch attachment. Locally, they’re sold as a frame, you’ve got to bolt on boards or whatnot to make it useful for your needs. (Here’s a link to a fully assembled one, but that’s not what I bought.) I bought the locally available frame and set to work.

The logical choice is to buy dimensional lumber and build from that. However, even the most expensive 2″ nominal wood you can get at a consumer outlet (like a place that rhymes with Home Despot) is crap. Seriously, the stuff they sell as “wood” is just embarrassingly low quality. How do they look in the mirror in the morning?

Luckily a tree fell across my driveway almost a decade ago. (The timeline of this story is mixed up… life is like that.) I hired some guy with a WoodMizer. Together we whacked the tree into planks. WoodMizer guys like making big fat giant beefy timbers. Slabbing up fifty dinky little 2″x4″ studs is a lot of work compared to milling three monster 2″x10″ beams. When I grow up I want to own a portable sawmill!

I had no purpose in mind for the wood, only the idea that it would be handy someday. I wound up with wood that would fit more in a medieval castle than a modern American house. I stacked it in my decrepit barn, a couple thousand board feet of timbers. It has been air drying ever since.

I brought the stuff out, birdshit and dirt and all. It was a bear to work with it. I couldn’t get the timbers onto my radial arm saw so I had to cut them with a handheld circular saw. I should have used a chainsaw. A circular saw was like a chipmunk trying to chew through a sequoia. None of my cuts were square, but it was the best I could do. I was happy the saw didn’t burst into flames.

Obviously, the wood was rough cut. It came off a bandmill, not the Home Despot supplier of wussy junk. Luckily, rough cut was fine. If you got a sliver off that mess it would probably be the size of a baseball bat anyway.

There is a process called “resawing”. Resawing is when you take a big fat honkin’ rough cut timber and work it down to smaller, finished face, pieces of wood. I ripped each of the planks to get an equal width and ran it through my thickness planer to get an equal thickness. I didn’t go overboard, this is meant for rough work. Think “toss a ton of firewood on it”, not “make an heirloom rocking chair”. It was hard work and I made a huge pile of sawdust while doing it. Thank goodness I already built a sawdust collection system!

There is a process called “resawing”. Resawing is when you take a big fat honkin’ rough cut timber and work it down to smaller, finished face, pieces of wood. I ripped each of the planks to get an equal width and ran it through my thickness planer to get an equal thickness. I didn’t go overboard, this is meant for rough work. Think “toss a ton of firewood on it”, not “make an heirloom rocking chair”. It was hard work and I made a huge pile of sawdust while doing it. Thank goodness I already built a sawdust collection system!

The finish product was pretty OK. It wasn’t as uniform as I’d like but the big heavy wood was a real workout for my decades old and fairly basic consumer grade woodworking equipment.

There’s something about a big plank that makes me happy. I would like to build a clipper ship out of this shit and sail the seas. Alas, a carryall is what I needed and that’s what I made.

I slapped on some basic waterproofing. Nothing special. I expect it to get beat to hell with use so I didn’t want to overdo the “fineness” of it.

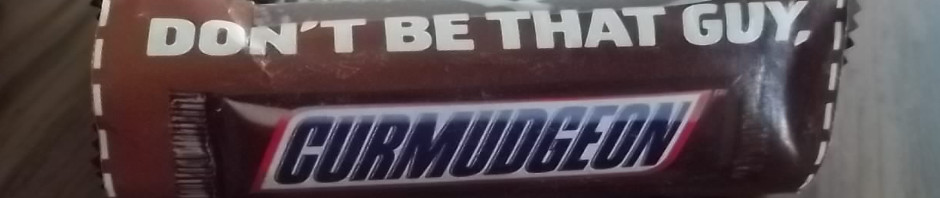

I bought some spiffy new drill bits so I could countersink the bolts. this was a special present for myself; an early Christmas present because I’d been a lucky Curmudgeon. Blog readers Bruce and Kristy send me a nice tip so I bought a shiny new set of Forstner Bits! I’ve always wanted Forstner bits. I spent the second half of the generous tip on a couple bottles of my favorite bourbon. So much joy… Bruce and Kristy, if you’re reading, y’all rock!

Like a ridiculously predictable blues song, my drill press took one look at my shiny new bits and malfunctioned. The bastard! The on/off switch got weirdly stuck “on”. Off is one thing but “stuck on” is a safety disaster! I have no intention winding up wrapped around a drill spindle!

Between the dead drill press and the rest of life, the entire project stalled. I made no progress for an entire year!

Ironically, huge beams will warp just like small boards. The tree that “donated” these planks was nothing great. When the fibers of the “resawn” boards were released, the planks warped… but only a little. With a small piece of wood, you can force it into alignment and all is fine. With these planks you could stand an elephant on them and they won’t give even 1/16″.

I could resaw them again. Or I could say “fuck it, it’s a farm implement”. Good for me that I didn’t overthink it. Everything lined up well within tolerances of big load bearing planks. Here it is just haphazardly tossed together.

I used paint sticks to add “drainage spacing” to the flat part of the carryall. My dumbass cat showed up to knock every damn one of them over. Cats suck!

I was going to crop this picture but Ms. Stihl from March 2016 was just too fuckin’ gorgeous to delete!

My drill bits, financed a whole year ago by a blog donation, were perfect. I drilled the countersink hole just exactly the right diameter for the washer and each one locked in like it had been welded there. I love it when things work out! (Also, yet another thanks to my donor who made my day a year ago and again this weekend!)

I had had bought all the hardware last year. I think it’s a sign that I might be slightly more mature than I once was because normally I’d have lost all the parts by now. Finding all those bolts right where I’d stashed them should be “assumed” but instead it’s like a lottery win. How often do you stash a part and then find it easily when you need it a year in the future?

It’s not rocket science; any monkey can build a simple carryall, but this particular monkey was proud of his work. The bolt heads are sunk deep enough that the surface is flat. I didn’t want to be stubbing my toe or mashing my fingers on bolt heads.

Ta da! Dirt simple and only 8 planks with 18 holes… you’d think I’d build it in a day… but life isn’t like that. Simple projects always take longer than you want. At the very least it’s built like a brick shithouse.

I’ve tested it out and I can hold just about the maximum weight that I ought to carry on my tractor. I toss some wood into the front bucket to make sure the front wheels are actually steering instead of just rolling. The front bucket and the carryall looks to haul 2 weeks wood in the coldest weather and a month in mellow conditions. Nice!

Have a great day y’all!

This post to me can be best described as “uplifting”, Thanks, AC! That’s some purty wood and there isn’t even any visible bloodstaining. Nice.

“How often do you stash a part and then find it easily when you need it a year in the future?”

Um, never? I have a five-minute electrical repair to do; I KNOW what I need is in storage. I’m approaching the one-year mark. Sigh.

Nice work!

I appreciate strong construction.

Those carry-alls look so handy. seen some youtube videos on fancy builds but like you i just need something to move stuff with. let us know how it works out please

So far it has worked great for cut & split firewood.

In the fine traditions of my family, I first thought “Why didn’t he just unplug the drill press and run an extension cord up to the press and plug it in when he’s ready to drill?”. Of course this is from the time-before-internet. And, “We gotta get this job done NOW boy!”

I did that a few times, but it sucks. If the only way to shut off the drill is more than an arm’s reach from the drill you deserve whatever happens when (not if) something goes wrong and you have to let go of the material you’re drilling to avoid getting wrapped around the spindle.

There is a grizzled one-eyed, three or four-fingered (depending on which hand), former safety guy mumbling to himself “Ya don’t eff around with rotatin’ stuff, dumbass!” OT, ask me what happens when somebody puts a 240 plug on a 120 drill…

If one is going to rant about “safety”, one should generally not use Forstner bits and bourbon at the same time…

Just sayin’…

Or get distracted by pin up photos on the wall behind the drill?

Nice! That should be good for your back – it has a lot of lumber support.

(sorry)

That’s the 2020 of puns. 🙂