[How y’all holding up under the 2020 shitshow? Everyone ok? Here’s a post with no politics and simple wood boards. We need a break.]

Things on a homestead never go according to plan. (Actually, life never goes according to plan, but that’s a different post.) Among my many first world problems was a window in my shop that had rotted away. Wind was whistling through the 1″+ gaps around what once was the edges. Last year I bought a cheap window to fit the rough opening, and then dropped the ball… for an entire year.

As long as you’re not dead you haven’t given up. Right?

Recently, I dug out the window, still miraculously undamaged and where I’d left it. I installed it. No biggie, except I did most of the work and it was the first window install I’ve done that didn’t piss me off.

The first part sucked. In the midst of a snowstorm I ripped out the old window. I had a friend help. There was a saw involved… and swearing.

Time for a digression. I used to think I hated carpentry. then I made a boat and it was a joy. This made me rethink things. What passes for “carpentry” in modern America is basically “construction”. One can be a “carpenter” and build a whole house and scarcely interact with wood at all. I hate that!

I recall a bathroom remodel that both sucked. It took forever, bled me dry, and it was a slog of learning new material after new material.

Under the guidance of someone smarter than me (thank God!), I tore layer after layer of shitty industrial wonder materials from 1970 off the studs. Then I reversed the process; slapping layer after layer of flimsy obnoxious “modern” industrial materials together to create the hybrid mess that is a modern house. I fucked with tile, grout, fiberglass insulation, low quality plywood, vinyl window sashes, Tyvek vapor barrier fabric, silicone sealant, PEX hose, a fiberglass tub, a porcelain commode, siding made out of God knows what, a rat’s nest of wires, drywall galore, and three coats of paint.

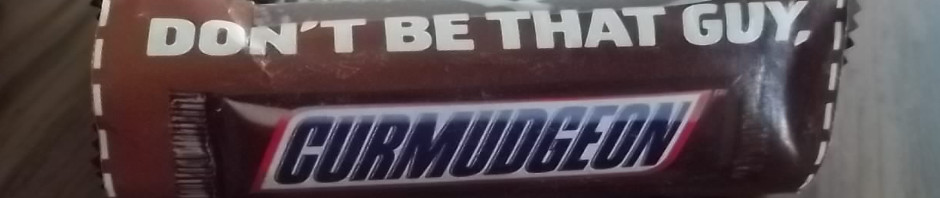

Did any of that involve a peaceful Curmudgeon working with actual wood? No! I call bullshit on the modern world. I like to work with wood… not whatever new sheet material Home Depot is spewing at consumers this fiscal quarter.

Back to this project, I removed a window that was once wood but was actually little pieces of wood scabbed together. The window was Plexiglas. The siding was some sort of Masonite atrocity that looks to me like marketers convinced people in 1970’s to side their houses with basically thick cardboard. It was a mess.

Gross!

Thank God I had help… and beer.

Anyway, the old shitty window bits were tossed and a new just as annoying vinyl window was tacked up. This took no time at all. The shop seemed a thousand degrees warmer. Then we quit. It was dark and snowing. There was more beer.

A few weeks later I was back at it. I was determined to regain lost ground. I’d experience the dead tree aspect of woodworking.

I said aloud to nobody “I’m going to do this job with some fucking wood”. It’s 2020, talking to myself aloud is the least of society’s worries.

The rough opening was a stud (the only wood in the wall) and a sheet of Tyvek and then some plywood. It’s butt ugly, but I like plywood walls in my shop. Drywall doesn’t suit me. Also this is a workshop. Only half of the wall is even built. Some of it is still disgusting, moldy sagging “bungalow paneling” some fucknut tacked up decades ago. All of Curmudgeon Compound is a work in progress.

Anyway I had some 1″ nominal (that’s 3/4″ on earth) pine that was leftover from another project. Some had been stained and some had not. Some was 3″ wide and some was 4″. I was determined to spend $0.

A chunk of stained 3″ wide pine filled the gap and covered up the rough wall. See it here on the bottom. It fit just right. I went around the perimeter with an unholy mix of stained and unstained. It would be better if all four sides were unbroken single boards and uniformly stained. However, IT’S A WORKSHOP! This is more than adequate for a workshop.

Once I had the perimeter done I put up a decorative “molding(?)” or “trim(?)” of 1″ x 4″ all around the window. I offset from the inner perimeter just about 1/4″ in all direction. It looks pretty spiffy having that little offset.

I cut the horizontal top and bottom trim a smidge long and then whacked a little triangle off that just to make something approaching visual appeal.

None of this is rocket science. Any chimp can do the same. I was just copying something I’d seen some other guy install. But it sure felt a lot more fun than messing with the vynil trim bits sold for window trim. Say it with me folks:

“Wood is a good material for building, vinyl is made for shitty disco albums.”

Oh no! The homebuilt dust collector I built is in the way. I hung it from a few pieces of maple leftover from my little sailboat build. I didn’t want to move the collector pipe or the support bits. It works surprisingly well and I’d rather not fiddle with that nice level pipe.

No sweat, just measure twice, figure out where the maple dust collector support will intrude on the area meant for the incoming pine trim. Then cut out exactly that area.

I expected a complete clusterfuck, but after measuring ever so carefully, I cut out notches so tight that they slipped together like puzzle pieces.

Sometimes things fit together so well… it just made me happy. I’m just a redneck fiddling around with pine in a garage but for a moment I felt like I’d crafted a fine thing. It was tight enough to support itself. It was loose enough to slide together without undue pressure. I didn’t split the very small trim part on the right side. I didn’t break anything, cut off a finger, or waste so much as an ounce of wood.

A thing made well, even if it’s a crude and simple thing, is a joy to the builder. It made me happy. You gotta’ enjoy the moments when they happen.

Here’s the right side. Just friction fit. I hadn’t even screwed it to the wall when I took this photo.

It was almost a shame to screw the piece down.

Here’s the other side. Again, I’ll admit, it’s not a finely crafted reproduction antique heritage rocking chair… it’s just a slab of trim. But it fit right and made me happy.

Here’s the whole thing. Note: the wall itself isn’t even done on the left side. That’s why there’s some loose Tyvek visible. But damn, some simple bits of 1″x3″ and 1″x4″ pine really spiffed things up. Sooner or later I’ll get out the stain and make the pieces match… maybe next year.

By the way, that silly looking dust collector “blast gate” I built a year and a half ago works great. (Links to my dust collector build: 1, 2, 3.) I had my doubts that my cheap little solution was as good as the expensive stuff but it works well and has held up better than anything that crude has a right to perform. Sometimes the simple solution is just right.

Yup…very satisfying, even from here, west middle Tennessee.

That’s a win in anybody’s book. Getting stuff done is what homesteads are all about.

Last fall I hung new cabinets in our pantry. Not rocket science, but not monkey shines either. My skeptical bride was pleasantly surprised at how nicely everything turned out once I was done. My reward for that high quality labor was a request to make a custom closet insert. I suppose that was a win too. She’s happy and that makes me happy.

Next in the list is a greenhouse. That will have to wait till the currently insane prices for lumber come down a bit. The hurricanes sure have driven up prices for building materials.

Thanks for a refreshing post. Building useful stuff puts all the foolishness of the chattering classes into perspective.

In my early 20’s I became a Union Carpenter Apprentice. We did very little with “modern “ materials our last classroom project was to build a 16’x24’ cabin-by ourselves. The only help was raising the walls. 6000 hours classroom and ojt and I became a Journeyman. Modern materials were used in commercial construction mostly cause they went up faster. Working with wood is a joy and feels more realistic somehow. Nice trim.

JFM

“Thank God I had help… and beer.”

Quit whining. If it was THAT bad you would have resorted to whisky. >};o)

The precision fit of the lower trim is no doubt a legacy of your boatbuilding effort. Getting a curvy and constantly changing shape of a boat to fit properly together makes things like that a doddle. Still, it is satisfying to see a job well executed. That’s nifty, that is!

Excellent. “What works” is an underrated measure – but this has a beauty all of its own.

Besides, after looking high and low, I still can’t find the nails my friend suggested. Does Finland even make nails?

Nails from Finland! I didn’t get that one for a few minutes.

Workin’ on the beard post now.