There’s nothing deep about today’s post. Don’t think I’m going to philosophize about “peace and love” or anything like that. Today is a depth free day!

A zillion years ago I almost bought a 3d printer. I did due diligence and researched it. I was broke and low on time and decided not to.

At the time, it seemed like 3d printers were in their infancy. Many were probably awesome but some sounded glitchy. (Remember, this is years ago.) I’d read posts of people struggling to turn out their first “Benchy”. (“Benchy” is a little toy boat that has features 3d people use to analyze their printer’s performance.) Various discussions delved into the deepest rabbit holes of FDM (fused deposition modeling) and there was CAD and G-code and all sorts of fascinating but daunting errata. The learning curve might well have been a cliff to climb.

I didn’t need another rabbit hole lined up with my HAM radios, and soldering irons, and welding kits, and garden, and tractor, and… well you get the point. I decided to wait.

But now is the time!

I just bought my very first 3d printer. It “feels” different than my research from many years ago. My new gadget is fun and “user friendly”. I don’t much know what I’m doing, yet the technology itself has matured sufficiently to drag my ignorant ass across the finish line.

Oh sure, the frontier is still there. Which is awesome! I look forward to learning cool things so I can make cooler stuff. I’ll surely play with the edges as I get more experience. There’s almost literally no limit; you can master 3d modeling, and “slicer” settings, and materials science, and all that… but one does not have to start out on “hard mode”.

I’ll start out making a pencil box and (if I stay motivated) progression to carbon fiber exhaust manifolds is up to me. None of that formerly brutal learning curve right at the beginning. (Also, a lot of people seem happy to make Christmas tree ornaments and tchotchkes; and that’s ok. If you want to top out making elf figurines and fidget spinners there’s nothing wrong with that.)

I’ve only had the thing a week and it’s just a blast. I’m happily flinging cheap reliable filament at easy, tested, models… and it works.

The results are spectacular. It really surprises me. Everything I’ve made so far has had at least the same fit and finish as an object you’d buy at WalMart and maybe better. The stuff I’m making isn’t heirloom quality but it’s not all striated and “gunky” either. So far, the things even a n00b like me can create look “commercially manufactured, consumer level, pretty good”.

I’m officially declaring “now” as the era when 3D printers have reached that sweet spot in technology; the moment when you can be an idiot and still use it happily.

I purchased a Bambulabs A1 Combo. The link goes to Amazon, if you buy anything from the link I get a few bucks and it costs you nothing. All printers are not the same. For a flat out beginner I recommend the path I’m taking.

Here’s a photo I grabbed from the Bambulabs website, so you know what I’m talking about.

Some notes:

Bambulabs feels a lot like Apple. The machine is easy to use but absolutely bad in terms of privacy, just like that infernal cell phone in your pocket. Other printers may be more private. Just like Apple, Babmulabs wants to merge everything and you gain all sorts of convenience that way. I can monitor my printer from my cell phone! I can even launch prints from cell phone. I can pick from a bazillion free and (so far) reliable prints on the “makerworld.com” site. I see a cool thing, click on it, and boom it’s printing. The “nerd index” is greatly reduced. On the other hand, I can also see what’s in the background of the printer’s camera. I also assume the People’s Republic of China and the FBI know what I’m printing. There are things you can do about privacy but it’s not the default. For the Bambulabs “environment” just assume James Comey and Xi Jinping are watching the printer like creepy privacy violating perverts.

It’s not the cheapest printer. You can get cheaper 3d printers which are (probably) just as good… but harder to use. There’s a value to “idiot proof” (or at least “idiot resistant”) and I was willing to pay it. The “ease of use” of this mad scientist’s tool has blown my mind.

It’s not the most powerful printer. If you’re running a business or have special skills you might want more. Temperature proof, nearly indestructible, super precise, exotic material prints might be hard on an “entry level” printer. Then again if you’re doing shit that specialized you don’t need to entertain some rando’s advice about your chosen skillset.

Multiple filaments turns the dial to 11! The “combo” has a hot shit, materials handling feature that completely changes the game. The “combo” is not just a 3d printer but an AMS. The AMS is a funky looking gadget that allows the printer to pick and chose from four different filaments. It does this, on the fly, and (within reason) automagically. I’m cranking out 4 color prints and all I’ve done is just click on builds and indicate which of 4 filaments to use. You don’t need multiple color / multiple material abilities, but it vastly expands your horizons.

Amazon has them on sale. But don’t be silly. Shop around. I bought mine directly from Bambulabs. One warning, it was shipped pretty slowly and that may be a Bambulabs thing more than an Amazon thing. I suspect buying from Bambulabs is slightly cheaper and buying from Amazon is slightly faster. YMMV. Also, buy a few spools of filament (usually well under $20) or you won’t have much fun with your new toy.

The Bambulabs Mini is cheaper and still good, but it can’t print big stuff. I didn’t buy the mini. I bought the full sized A1 printer. It can churn out anything that fits in about a 10″ cube. The Mini saves you about a c-note but can only make smaller things. Aside from the smaller build envelope, I’ve heard nothing wrong about the Mini. Both use the same AMS which is the real showstopper of the combo.

If you’ll only do mini-figurines, you might want resin. Most 3d printers pull plastic filament off spools and lay it down in layers. They can make mini-figurines that are “pretty good” (plus they can make “everything else”). Resin (a very different technology) is superior at mini-figurines. I’m talking “get out a magnifying glass and count the hairs on Gimli’s head” precision. If you’re extremely uptight and like mini-figurines you may want a resin printer. Resin printers use chemical goop and light; it’s a different animal. I think they limit you to one color but if you’re the kind of cat that wants to count the scales on Gimili’s armor you probably like painting mini-figures. (Note: the Bambulabs Mini is ideally sized for mini-figures but that assumes you can live with “very good but not blown away” quality.)

I’m not saying material goods are the point of Christmas. I’m just sayin’ there are times when a technology catches a wave. I feel like that happened for 3d printing with the A1 Combo. As always YMMV.

A.C.

P.S. Remember, Christmas isn’t about stuff. If an A1 Combo will break your bank don’t freak out. I waited over a decade and the technology only got better. Maybe cooling your jets will work for you as well as it did for me?

So how many items have you printed for the dog?

Or do you NOT want Mama to be happy at Christmas?

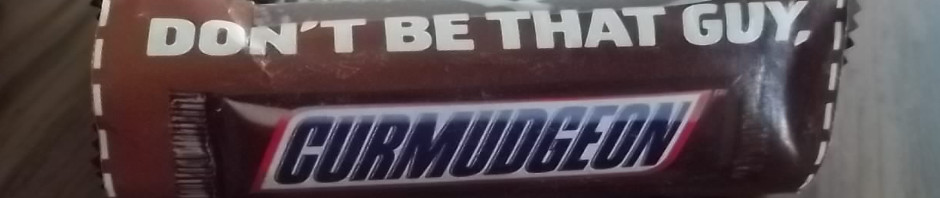

No dog toys so far. All I’ve printed is PLA and I know Mrs. Curmudgeon would freak out if I fed the dog plastic. The dog would be perfectly happy with it though.

Sounds like a lot of fun. On Leno’s Garage a coupla years ago he was showing off his printer. He showed us a crescent wrench. Spin the adjuster and the wrench adjusted. It was plastic, but that printer injected a Buffer into the the places where moving parts went. IIRC all that was required was get it hot and melt the buffer stuff out. I’d like to play with one.

Show me a 3D printer that can copy itself, and I’ll buy it. And return it shortly after….

Stefan v.

A 3d printer can’t quite replicate itself but it’s darned close. I imagine a skilled operator could do it if needed, like on long cargo boat trips or incredibly remote places? And maybe someday they’ll do it in space too.

Back at the inception of the 3d printer idea there was talk of having them in a “library”. Check it out, make your own, and hand it back. Sadly they’re a little too “tinkery” for that level of sci-fi awesome.

I’ve only had mine a short while and did a “bootstrap repair”. It worked out perfectly!

A Bambulab PLA filament spool on the AMS lite popped open and partially tangled the filament. I used a different spool of PLA to make a threaded device to squeeze the spool back together. Then I hung the spool on some zip ties and it worked “well enough” (although the filament was still a little tangled). I used the “fixed spool” to print a new spool and also to print a crank handle. I used the AMS lite and the handle to wind the filament off the “bad” spool and onto the “new” one. I’m absolutely shocked that it worked. I also re-used the “bad” spool for a refill pack of filament. (It wasn’t broke, it just came loose internally.)

So I didn’t bootstrap the whole machine but I “rescued” a roll of filament and made my own spool. That’s a start.

P.S. I’m mostly using PLA and a little PETG. The PLA put up with all that manhandling just fine. I don’t know if other filaments are so forgiving.

I have two Ender3v2s from amazon. (They’re cheap, and they run locally.) I use PrusaSlicer to turn the .stl shape files into programs. I’ve recently been using them to 3d-print all sorts of spacers and post-holders and bases for an optical breadboard thing I’m doing at work.

I have some hole sizes (adjusted from the usual drill and tap chart) that I tap for screw holes. If you’re interested in any of this, I could figure out how to send example files. I imagine you want to climb the learning curve with your own projects first though.

I use a program called OpenSCAD to design my parts.

-Madrocketsci

I’m still just learning but that’s the fun part. Every step is a hoot.

I started with makerworld, which is almost perfectly synchronized with Bambulab printers. (And probably sends everything it knows about me directly to China and probably the NSA too… because that’s the dumb world in which we live.) I was just downloading crap straight through Bambu studio and letting the defaults do their thing. That works very well. Then I started tweaking designs in Bambu Studio; just adding text and changing colors. Recently I sniffed out a random *.stl and downloaded it. This went through the Bambu studio slicer without drama. Removing the supports was a bitch so I changed the supports and tried again; which also worked.

Every new thing is a fun experiment. I can see the rabbit hole goes deep!

I have been looking for an affordable 3D printer. This one looks really good. Is there anyway to bypass the spying issue with this brand. Thank you. I look forward to reading your posts everyday.

Oh yeah, there are about a thousand things you can do to bypass the spying issue. You can air gap it and run from micro SD (it’s equipped with a micro SD slot). Just keep it off your network. Etc… None of this is particularly hard and I think you could safely make the thing completely trustworthy.

However, as a complete N00b I’m doing none of that. I started out dropping models straight from makerworld, straight through Bambulabs Studio, through the cloud and into the printer. It works stupidly easy and that’s what I wanted (at least at first). Now I’m grabbing models from all over the place and randomly “tweaking” them in Studio (which is the slicer). It’s quite a forgiving environment. Maybe in a few years I’ll be writing g-code and running the thing so off grid it’s on a generator. There’s no rush.

If you want a 3d printer go for it. The one I got is a lot less “tinkery” than they once were. (I can’t vouch for others.) Also it’s user friendly while simultaneously preserving all sorts of technical rabbit holes to explore.

Glad you like my posts.