A few years ago I spent an afternoon ripping dimension lumber. My shop got so dusty the air was like fog. At some point “toughing it out” is dumb and bad for your health. (Also the dust was screwing up a fiberglass / epoxy project I was working on!)

I decided to do something. (Unlike politicians, when I say I’ll “do something” I actually do it.)

I’m a cheap cuss so I scoured Craigslist. I scored a dust collector that looks almost exactly like this: Below you’ll find a link to it on Amazon. Note: I don’t have that model, I have a older one of a brand I don’t recognize. However, in design and components they seem functionally identical. Both have 1HP motors and I can’t see what would be different about them. If both sawdust sucking machines are 1 HP and suck sawdust adequately what could be different; Fahrvergnügen, Corinthian leather, Martinizing?

Below you’ll find a link to it on Amazon. Note: I don’t have that model, I have a older one of a brand I don’t recognize. However, in design and components they seem functionally identical. Both have 1HP motors and I can’t see what would be different about them. If both sawdust sucking machines are 1 HP and suck sawdust adequately what could be different; Fahrvergnügen, Corinthian leather, Martinizing?

I got it for roughly half the cost of buying new. Note: In retrospect (and rechecking my Amazon link) I think I got my Craigslist version for under a third the cost of a new one. I rock!

The only difference between my model (dated 1995) and the one on Amazon is that mine is a different color, a no name brand, and lacks wheels. (I could slap on $15 worth of wheels but so far it hasn’t been necessary. You don’t move a sawdust collector so much as route its function with hose.)

Also 1995 is 24 years ago unless you learned new math in American public school in which case it’s 14 years if you feel it ought to be. 🙂

Like all Craigslist purchases, acquiring it was interesting. After a bit of phone tag, I met some dude in a parking lot a day’s drive from my house. (I was traveling.) I know what you’re thinking when I say “some dude” but this guy was wearing a suit and tie. It was just before a city’s rush hour morning commute and we met in a bank parking lot that wasn’t his office and wasn’t yet open; just a mutually convenient highway exit. He was probably on his way to some corporate CEO gig while I was on my way to freeze my ass in the middle of nowhere.

We unloaded the dusty old collector from his Lexus and tossed it in my Dodge. (Who carries a sawdust collector in a Lexus?) I paid cash. I also reflected how the machine was changing position in the class structure. Destined to an uncertain future in the heart of redneck “frugality”; it left a heated Lexus and wound up stuffed it in a garbage bag and lying on a snowy truck bed.

I stuck up a conversation with Tie-boy (yes, I have biases… lots of people wear ties and he was probably a really nice guy. Also he probably though of me as Bearded Dumbass.) However, there’s a method to my madness, whenever I buy anything on Craigslist I talk to the seller enough to satisfy myself I’m not buying stolen shit. If I smell anything fishy, the deal’s off. I was thinking “who’d you get this collector from”? My initial impression being he was selling Grandpa’s old shit. Maybe putting the proceeds towards payments on his McMansion, trophy wife, or the Lexus. (I’m terribly biased.)

After five minutes talking it was clear my impressions were wrong. He was quite knowledgeable. Likely he does higher end woodworking (as a hobby) that I could do if my life depended on it. I got the idea he had two separate and independent dust collectors serving a veritable army of expensive stationary woodworking machines. I think he was ditching this old one so he’d have a matched pair of collectors. I think a matched pair of any power equipment is pretty awesome!

It just goes to show you can’t judge the Tie-boy by his Lexus.

At home I was delighted to verify I hadn’t been screwed. It ran great. Also not too loud… which is delightful.

When you fire up a collector of this type the upper bag inflates. (The upper bag is a cyclone area, the dust goes into the lower bag.) The Jet model in the picture has a hanging rod that looks like an IV Bag holder. It keeps the bag in place when it’s deflated. Mine lacks that; probably never had it. I ran it for a while without any bag suspension (I doubt it matters) but just to be sure I eventually strung p-cord from the ceiling to the bag. It looks silly but works great.

The bag had another surprise. Someone had dripped a string of paint dots on the bag. This has no effect on the bag’s function. It’s hardly noticeable…

WAIT A MINUTE! Are those paint dots or blood?

I got out a lens and examined closely. I think they’re blood droplets! I’m not NCIS and I’m not going to send it to a lab and I honestly think “blood spatter analysis” is at best a crude guess (unlike the voodoo magic they imply on TV)… but I suspect my sawdust collector has seen things. (Either that or it’s just paint and I have an active imagination.) Think about it, this machine has spent nearly a quarter century servicing groups of stationary woodworking machines; all are capable of lopping off a few fingers in a nanosecond. Is it totally improbably that someone’s severed pinkie has bounced off this machine? Regardless, the machine works and it’s just a few drops, not something from a horror movie. (I kinda’ like the detail too. It gives it “character” and reminds me to be careful, which is a good thing.)

In case you’re wondering, Tie-boy had all ten. I think. I wasn’t specifically looking.

Back to mundane logistics, the collector is just part of the puzzle. For a while I used it with a single hose clamped to one machine at a time. What a PITA.

For any semblance of convenience, you need to route suction from the collector to all of your dust sources (i.e. your stationary wood cutting/finger lopping machines). Note: I’ve been purposely trying to learn hand tools too. One of the cool things about chisels and hand planes is that you make a lot less dust and a lot less noise. It’s vastly more peaceful. You can go Zen with a plane, but with a table saw you need your head in the game! I try to use hand tools as much as possible. Don’t laugh, it may be a dying art but hand tools are amazingly useful. Some of the time they’re almost as fast (or faster) than power equipment and often they’re more precise. (Hand tools can lop off a finger too, some things are always the same.)

Back at the ranch… I needed to route suction to all of my power tools. The obvious solution for is hose made for that purpose. Duh! In my case 4″ hose. It should look like this:

Here’s the amazon link. And no, I don’t have any cool hose like that .

Here’s the amazon link. And no, I don’t have any cool hose like that .

The nearest place I could find suitable hose is 80 miles away. It was opaque (clear would be much better) and it was expensive. I bought one 10′ section. It worked OK but it just killed me to pay the high price. Even on Amazon you’re in the ballpark of $3 a foot. As you’ll see later, most of my system is based on 4″ thinwall sewer/vent pipe. I lost the receipt but I suspect pipe goes for a buck a foot or so. Roughly 2/3 less than special purpose clear hose.

Setting up a dust collector properly can nickel and dime you to death!

But wait, there’s more. In my case I have 4 machines that are dust makers; a table saw, a thickness planer, a radial arm saw, and a bandsaw. If I route to all four and turn on the suction, it won’t work. It’ll lack the power to clear the machine in use if simultaneously wasting 3/4 of its flow on three currently unused machines.

Enter the device with the best name ever; blast gates. A blast gate is an overly awesome sounding way to say “valve” for your suction hose. The blast gate on vacuum hose functions just like a gate valve on a water pipe. With the delightful twist that you don’t have to get uptight about sawdust. A leaky pipe is a big deal but a little dust leaking out of a fitting in your shop is completely irrelevant. That’s why I built my system to be mostly friction fit together. I’m good with PVC and pipe cementing but for dust I stuffed ’em together like Tinkertoys. That way I can pull it apart if (when!) something clogs. Also I can easily reconfigure if (when!) I decide I deserve (need!) another stationary power tool.

Some blast gates are plastic and look comically chintzy. The grossed me out on principle. Here’s what appears to be a medium quality aluminum model:

Here’s the Amazon link. (No, I don’t have any commercially made blast gates. See the pattern?)

Even if I was willing to spend the scratch, it pissed me off that I can’t buy one within 100 miles of my house. Even the place with the overpriced hose was out of gates. WTF! Everyone in the goddamn world has a table saw and all I wanted to do was “level up” to keep my lungs a bit safer and suddenly I’m shopping for exotic shit? In a world where I can buy 60 kinds of yogurt in any grocery store, how hard should it be to locally stock a few dust collection components? Also, get those damn kids off my lawn!

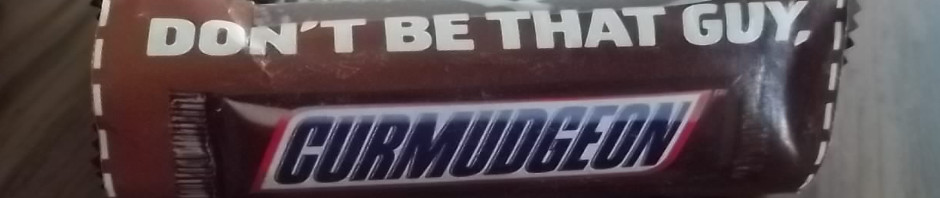

Lucky for me I’m an Adaptive Curmudgeon. It’s sawdust, not uranium. Also God and Al Gore gave us the internet. There are a million you-tube videos of how to fabricate all this crap. The videos are all made by people who are better woodworkers than me (a few of them may own a Lexus). I watched a couple to get the idea and subsequently made mine entirely as I saw fit.

So, aside from the 24 year old vac and one length of opaque hose, I built everything else from scratch or local sources. I used 1/4″ plywood, adhesive, sewer pipe, and a pile of shop vac accessories I found at the local hardware store. It wasn’t free but I estimate it was well under half the cost of buying new components. Also it doesn’t look too ugly and it seems to work perfectly.

This is the internet so pics or it didn’t happen. Stay tuned.

I wouldn’t worry too much about the ‘blood’ spots. The same Craftsman table saw took a blood sample from by right thumb (tripping plywood kickback) and my dad’s right ring finger knuckle (stack dado cutter kickback). We were both fortunate to only get stitches and scar.

My only hope is that I don’t add to the machine’s lifetime experiences. 🙂

Since you mentioned safety, I could use some opinions about radial arm saws. You might know more than me on this topic; I’m not a total N00B but I’m not a seasoned veteran of woodcraft either.

My Craftsman radial arm saw is old (probably 1960’s or maybe early 1970’s?). I’ve only been using it a few years. I got it super cheap and it works mostly OK. However, I notice nobody seems to use radial arm saws any more. (Also I need to rejigger the saw’s table with some new sheet material… it’s pretty worn.) Now the stores rarely seem to stock radial arm saws and I guess they push miter saws instead? I believe the term I’m looking for is “sliding miter saw”. The few times I used one they were hot shit. Are they safer and easier to use than a 50 year old radial arm saw or about the same. Aside from ripping (which I prefer to do on a table saw) I assume miter saws do basically the same cuts as a radial arm saw? Is it worth it to drop a couple hundred to “upgrade” to a mid-level miter saw or should I keep my wallet clamped tight and continue using my “antique”?

I may be wrong, but the sliding miter seems to offer compound angles and take less real estate in the shop. My dad had a radial arm for awhile, I don’t recall it being particularly outstanding. He sold it when he got his Shopsmith, a machine I loved and hated; it did a lot of things mediocre, but it put a lot of equipment in a relatively small footprint.

A sliding-compound-miter-saw allows you to push the blade into the wood because the blade pivots up. A radial arm saw doesn’t have that function so it’s likely to ride up onto the work-piece (or so I’ve heard…I’ve never used one myself).

If I were buying one new I’d probably get one of the low-profile versions like the Craftsman (hope that link works). Festool makes a similar one, but Festool is very proud of its products and that’s reflected in the pricing.

In that model, the saw rides on fixed tubes. Mine, the tubes and the saw slide forward and back through a support point, which doubles the depth I need just to use the darn thing:-(.

Their is only one problem with using PVC for dust collection, and it’s the same reason that the flex hose is so expensive – Static!

I hope you have a grounded wire running through that pipe, or someday you’ll have an explosion!

Almost anything ground finely and well mixed with air is explosive, but traditionally flammable materials are the worst – wood, coal, flour, etc.

I plan on grounding… though I haven’t figured it out yet. I setup the pipe as a long straight shot. My logic is that it won’t be hard to shove a grounding wire from end to end right inside the pipe. That ought to handle any charge issues very well.

Also everyone freaks out about explosions but I suspect they overestimate risk by conflating “big sawmill/factory explodes” with “Curmudgeon dicing up studs to make a sawbuck churning out half a cup of sawdust over 20 minutes”. After all, nobody loses sleep over a shop vac with a 10′ plastic hose and how is that different? I’d be more worried if the plastic pipe thing wasn’t so common. I suspect 3/4 of (privately owned) dust collection systems have pipe as the main component. The only place I see lots of the flexible high end corrugated special purpose stuff is schools and factories; the land of high production and/or OSHA.

That said, once I run the grounding cable what do I hook it to? I’m not losing sleep in a shop with reasonably high humidity and low actual production but grounding is easy so I’ll do it. But where? The floor is concrete. The wall is plywood. Run the wire to my big metal woodstove?

a 1 lb bag of flour spread thru the air and a firecracker will level a small house. a cup of sawdust in the right sized room will ruin your day. grounding shouldnt be hard. you can pick up 14 or 16 solid copper wire at virtually any of the big box places for not a lot. couple clamps and yer good. may want to bond the machines to the tube as well; reduce any chance of sparking at the source… cheap insurance.

For bonding I was thinking a glob of adhesive at the start and end of the 15′ run.

Take a look at the grizzly instructions on page 32. Your system is probably similar. My GUESS is you’re ok without grounding as far as fire is concerned. However we have two CNC routers and before we grounded the hoses you would get quite a zap if you brushed up against one.

http://cdn3.grizzly.com/manuals/g0548z_m.pdf

BINGO!

That’s the information I needed. I’ll do a ground wire as instructed on page 32 and the Gods of Static Discharge will be mollified.

Thanks!

Oh come on now! How is your dog going to be entertained appropriately if you do not do the “Static Dance” frequently???

}:-]

Yes, that’s why I not freaking out about static… it’s because of my dog. 🙂

Nicer setup than mine, I went big shop vac and cyclone separator for my basement shop.

Works for Sanders, table saws and miter saw as well as normal shop cleanup.

I like what I made but a shop vac would’ve been a lot easier.

For a starter set of dust collection hose and fittings, take a look at Harbor Freight.

They have a flat rate shipping fee, and it ends up being a reasonable cost.

I haven’t bought their hose yet, but I’ve moved it into and out of the online shopping cart a couple of times.

Eventually I’ll push the button and try it.

Good advice but I already went for it and made my own. It’s (mostly) a done deal now.

By the way, as long as you were counting in base 20, then 14 years would be correct.

Ha ha ha… I’m going to do my taxes in base 20!

Pingback: Small Victory | Adaptive Curmudgeon