I got a lot of good advice about just using a replacement bow saw blade. Either that or using a bandsaw blade and cutting to length. (Bonus points on that last one for being super adaptive!) Since I’m kinda’ digging the idea of restoring this saw I did some checking myself. Here are some more details.

#1: It’s a bucksaw. When I search on DuckDuckGo “bucksaw” turns up a zillion photos of exactly what I have. (You’re not searching on Google are you? You gotta’ watch out for Google. They’re evil motherfuckers… I’m just sayin.) Lots of people use bowsaw and bucksaw interchangeably but for my purposes if it’s old and wood and looks like a pioneer would use it, then it’s a bucksaw. If it’s not old, not wood, and a pioneer would throw his heavy bucksaw in a lake as soon as he got his hands on this lighter modern device, it’s a bowsaw.

#2: It’s way thicker than a bowsaw. I’m talking here of thickness of the blade, not merely length.

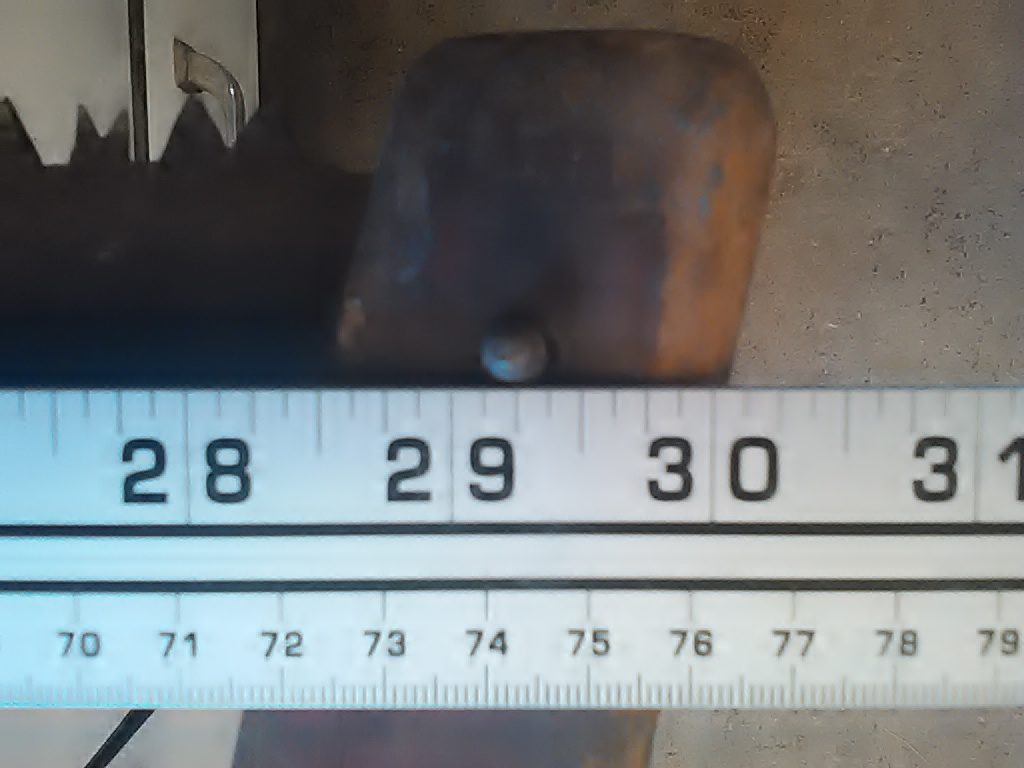

#3 I estimate it’s 1 7/8″ thick. A regular bowsaw is a lot thinner. Though I suppose there’s no reason the thinner bowsaw blade won’t work as well as the thicker bucksaw blade. The only thing doing work are the teeth. The only drawback is that it won’t look right.

#4 Lengthwise I estimate it’s 29 1/4″ from “pin to pin”. I still haven’t figured out how to remove and replace those pins. On the one hand I don’t want to totally trash the cool old saw. On the other hand I want a working object and not a wall hanger. If I wind up with wingnuts and a bolt I’ll just have to face what I’ve done. (I’m no wimp about messing with old stuff so long as it’s cheap. Don’t ask what I’ve done to some old Mosin Nagants.)

#5 I’m not sure but I don’t think bandsaw blades will do. The bucksaw has cutter teeth and rakers. The bandsaw has no rakers. I think for human powered cutting, I need rakers to get the sawdust out of the kerf. (Also, either the photo sucks of my bandsaw totally needs a new blade too.)

#6 I’m starting to decode the cutter teeth count. My old bucksaw has 2 cutter teeth between each raker. My modern (cheapo) bowsaw has 4 cutter teeth between rakers. This bowsaw blade is $11 and 4 cutters per raker. It says it’s for green wood:

Thus I suspect 2 cutters/raker is for dry and 4 cutters/raker is for green.

https://paulsellers.com/2015/10/blades-for-my-bow-saw/

The bandsaw blade idea was EXACTLY what I was aiming for. Try here. Not cheap but you’ll get plenty of blades out of one.

https://www.mcmaster.com/#band-saw-blades/=1bsdsc7

Perhaps these guys can help…

https://www.highlandwoodworking.com/bow-saw-frame-saws-blades.aspx

I am not positive, but I think bow/buck saw is designed to cut on both the pull a push strokes. Take a look at the geometry on the two picture you posted, especially the green wood blade. As far as the blade width I believe the wider blade will allow you to cut a straighter line. Think about how your band saw works. I have cut pretty straight lines with a 3/8″ blade before but it is far easier in my experience to do it with a 3/4 or 1″ blade. The resaw blades we use at work are 1.25″ with a 2 or 4 tooth per inch blade depending on how wide a board we are cutting.

All this from a guy who has never used a saw like you have, so take it all with a grain of salt.

Sam

Exactly! The cutting teeth on an old school saw like my bucksaw cut either left side of the kerf or right side. They are direction agnostic. Then the chisel teeth (or I call them rakers) chisel the wood from that gap. The wood fiber is already severed on the left and right sides so it comes out pretty well. And the rakers are dual sided, so they happily chisel either forward or backward.

This is unlike a regular hand saw or a mechanical bandsaw. They only cut on the forward stroke. (Just to be weird I have a Japanese pull saw (they’re cheap) that only cuts on the backwards stroke I use that when I need to “cheat” by flexing the blade or just want a very thin cut.)

You hit the nail on the head with the “cuts both ways” thing and I wasn’t properly articulating it. Thanks!

Unseasoned timber requires rankers as the damp sawdust clogs things up. Yesterday I put bandsaw blade but I should have been more clear. You need a resaw blade which is much wider and with far more aggressive teeth. Any local joinery will probably have a couple of broken blades which have either snapped or have a couple of teeth missing. The rivets holding the blades are usually soft aluminium or alloy and you can normally squash the head with a pair of pliers and pull it out then recrown it upon refitting if you want to keep it original or if like me you are simply as tight as a ducks bottom!

I will look into “resaw blade”. I wasn’t clear on the details.

The pins were driven in. Drive them out with an appropriately sized punch, being careful to support the handle holding the pin with a socket or something similar whilst driving. My preference for stuff like that is to drill a hole in a 2xwhatever that has a large enough diameter to let you make sure the pin is over the hole while you drive.

The 29.25000″ may be the length of your current blade, but that turnbuckle at the top which lets you tension the blade can also accommodate some length variation. Don’t overthink this.

And hopefully I don’t need to tell you this, but make sure you loosen the turnbuckle before you drive out the pins. Don’t be surprised if the saw becomes “wobbly” with that turnbuckle loose. The spreaders are mortised into the arms but not secured in any other way. THAT is why the blade length isn’t that critical. Although you wouldn’t want to try to use either a 24″ or 36″ bow saw blade…

Ha ha ha… I’ve already overthought it. I have wasted so much time looking for the perfect replacement blade. I’m really surprised I can’t just buy a duplicate of what I’ve already got.

But I was aware of the turnbuckle and figured I had a generous amount of play in the blade length. The pin looks like an old nail. It may be peened into place. I’ll figure it out when the time comes. I think I’ll replace with a new pin.

Might be smarter to reuse the old pin since you know it fits properly. The tension from the turnbuckle keeps the pins in place as long as the turnbuckles are tight and the pin isn’t too sloppy a fit.

Good point. OK, the old pin doesn’t go into the trash until I’m sure it’s not needed.

I have to tell you that I have several of those modern bowsaws with dry wood blades and they’re awesome. They just hum through the dead dry red oak I have here.