Warning: this is a long post. Usually I shy away from anything too long, detailed, or technical. I’m just an idiot on the internet and who’s got patience for that? That said, I like my solution so much I had to post the details. If you’re not interested go ahead and bail. (I won’t take it personally.) Next week (or whenever) I’ll revert to bitching about politicians, relating raccoon attacks, or setting tractors on fire.

In case you’re wondering the woodsplitter is already upgraded. In comments (and in person) I got lots of advice on ways to get the job done. Trust me folks, I considered them all. None were bad ideas. All would get the job done. But only one approach appealed to my perfectionist (at least in terms of woodsplitters) nature.

Since none of the obvious solutions suited me I took time to ponder. I finally relented and ordered an axle made to my exact specifications.

Replacing a splitter’s shitty little tires with a custom axle goes to eleven. It crosses the event horizon of wood splitter excellence and becomes mechanical wizardry. It’s that nice. Sure, there are cheaper solutions; bolt on a minivan axle, weld on a bigger spindle, toss the splitter on a trailer but none come out so efficient and dare I say it… sexy. (Good engineering is sexy and I’m talking about intellectual appreciation of machine matched to task. Dammit… get your mind outta’ the gutter.)

So I, the cheapest guy in creation, pried open my wallet, bit the bullet, measured and remeasured again, and filled out the worlds most complicated form. A few weeks later I had a bespoke axle. It was the smartest thing I’ve done in years. I wish I’d done it on day one.

For the six people on earth who own a wood splitter, use it a lot, and want it to tow it like they’re in the Dukes of Hazard, seek these attributes:

- Low weight (750 pounds or so). The factory specs for my splitter say it weighs about 600 pounds. So I added a margin for a full tank and one hefty chunk of wood. Don’t go overboard.

- Reverse angle (with the axle lower than the spindle). It’s a low rider!

- Five bolt hubs (because four bolts are stupid).

- Precisely the right width.

The key here is the Goldilocks solution. Rein in your manly desire to go overboard and bolt on 33″ Super Swampers. Seek the middle ground that matches the task at hand.

Lets start with what’s called half axles. That’s how you’ll likely find the part for sale. A kind reader sent a link to a set of axle halves at Northern Tool (for $189) and I saw about the same thing at Amazon (for $159). You’ll find them in all sorts of sources but I couldn’t find any sitting on a shelf in a store. (I do live in the middle of nowhere.) Here’s a picture (they all look about the same).

It looks great but the first problem is that it’s a 2000 pound set (the two halves, working together, are tuned for a 2,000 pound load). Putting a 600 pound splitter on a 2000 pound set means the suspension is going to be underloaded. It won’t flex and that’s part of what got my ass in a sling in the first place. The goal here is to have

It looks great but the first problem is that it’s a 2000 pound set (the two halves, working together, are tuned for a 2,000 pound load). Putting a 600 pound splitter on a 2000 pound set means the suspension is going to be underloaded. It won’t flex and that’s part of what got my ass in a sling in the first place. The goal here is to have a functioning suspension an awesome suspension. If you’re going to win car races while towing a wood splitter you need just the right amount of flex. When I ordered an axle I had a list of weights to choose from. If you custom order you will too. I think I selected something like 750 pounds.

Listen up fellas, this is one place where “overengineered” is inferior. The best suspension is the one meant for precisely the weight you’ll be towing.

Added bonus; that flex makes using the splitter a smidge more forgiving. When I smack a heavy chunk of wood on the beam I don’t get vibration in my hands and don’t send a shock resonating down the splitter’s components. Instead it gives just a bit. Nice!

. . .

The next part is the direction of the flex. Nearly all (90%?) torsion axles are meant for the spindle to be lower than the axle itself. (In the picture above, the axle parts are actually upside down.) This just plain makes sense most of the time but not on a splitter. If you start with axle components mounted beneath the splitter’s oil reservoir and then set the angle to put the spindle lower than the axle components your end result will be a very tall wood splitter.

Some say I obsessed over keeping the beam where it was. That’s because I did. Right now it seems about right. If it were any lower I’d be bending my back and that’s ungood. On the other hand every inch the beam is raised means I’d going to have to lift twelve friggin tons per year another bloody inch. There’s a technical term for lifting weight; that term is work!

Time for a Curmudgeonly Gem Of Insight:

“Work is done when a force that is applied to an object moves that object. The work is calculated by multiplying the force by the amount of movement of an object (W = F * d).”

Thus:

“Use your big monkey brain to manage the universe to minimize the work needed while not indulging your apelike capacity to sit on your ass eating Cheetoes all day.”

When I custom ordered my axles I could choose from several angles…including “reverse” angles where the spindle is higher than the axle. I called it the “low rider” option. I ordered axles with a reverse angle. The guy who was helping me place the order had never even heard of someone wanting such a thing… but when he saw my splitter he understood.

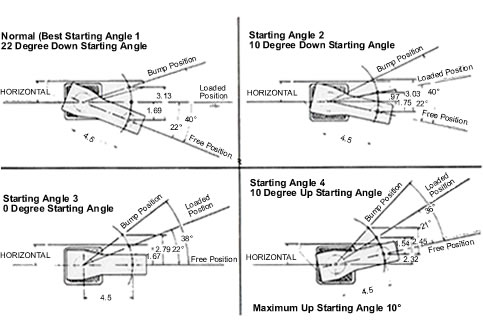

Here’s torsion axle image I found randomly on the internet. I had to fill out a form with all these numbers. If you’re an adult who slept through high school trigonometry decades ago the form might cause you to break out in hives. If you’re currently in public schools “trigonometry” is a dark art your teacher didn’t study in teacherology classes and and therefore you’re eventually going to die in a mud hut when all the old people are gone. Sorry to break it to you that way but you might as well know now.

Also, you shouldn’t mount torsion axles in a way opposite the way they’re meant to go. (Just flipping them over, is OK for leaf springs but not for torsion axles.)

. . .

In between the axle halves there’s this thing with a nifty name… the axle. Welding guys totally love fabricating them and welding them onto half axles. For some reason it’s like their favorite activity. I don’t know why. If you must weld up your own axle then metal isn’t overly expensive and if you hire a welder they’ll stampeded to do it.

In my case I was buying the whole thing as a fully assembled unit. All I had to so was add some numbers on a form to specify my desired width.

Width came out very nicely. Remember I didn’t want to go too wide and create an ergonomic disaster. I had to give the torsion axle room to flex without hitting the frame and that ended up being about 3″ wider per side than the spindles welded to the frame. You hardly notice it while working and I was happy that I could squeeze that extra width into the system so seamlessly.

Nobody explained to me why I needed an axle at all (instead of just having the two halves welded to the hydraulic reservior/frame). I finally just accepted that it must be so. I do like that there’s darned near no torsional stress on the reservoir now (unlike it was in OEM form). I don’t think it’ll matter but who knows if skipping the axle would lead to stress fractures in a couple decades?

By now you’ve got something that looks like this Torsion Trailer Axle (which you could have bought fully assembled for $229 and therefore avoided the scary order form). But don’t fret… the odds of finding one pre assembled at the exact width for a tiny wood splitter was nil anyway.

Also note the length of those two mounting points. It can’t be too long. Remember that the oil reservoir is only 5″ or so. YMMV.

. . .

You’re done right? Hell no! Now you’ve got to get hubs.

Now I get to feel smug! Remember all that money you saved by getting the half axles on sale at Northern Tool? Then remember how you saved money by using some junkyard scrap for the axle itself? Do you think you’re totally saving a shitload over that rich prissy Curmudgeon with his bespoke axle?

Oh you forgot about the hubs? Shocker! The Hub Kit you see below is precisely what you’ll need. Some are cheaper and some are more expensive. This one costs $40.06 but you can probably find the parts cheaper if you shop around. Did I mention you’ll need two?

The custom axle I ordered came with both hubs pre-installed. The lug nuts were included in a plastic bag taped to the axle too. That’s the gearhead equivalent of a hotel putting a mint on your pillow. Very thoughtful.

. . .

All that’s left is the tires. They didn’t come with my custom axle and they sure as hell won’t come with the hubs and axle halves you’re picking up at Northern Tool. On the other hand five lug trailer tires are dirt cheap, everyone has them, they’re always in stock.

They’re so damn cheap that you can get the tire, already mounted on the wheel, for less than your average truck’s hubcap. It’s almost confusingly cheap. I found these tires on Amazon for $31.95 but you can definitely do better if you shop around. I did.

I forgot how much I paid but it seemed shockingly low for what you’re getting. I swear trailer supply shops will rake you over the coals for a lugnut but then toss mounted wheel/tire sets at you for the price they came off the container ship from China. Go figure. They’re all about the same. They’ve all probably still got Chinese air in them.

For a splitter Load Range B is fine. Going for a higher load range isn’t going to do you much good so don’t bother.

There are two kinds of tire. High speed (which means highway and not racing y’all) and not high speed (which is the shit I started with). Unless it’s going on a wheelbarrow don’t even think of buying the non-high speed tires. Duh!

. . .

Lights probably aren’t necessary but c’mon, you’ve already gone the extra mile. Do you really want the hassle when some dipshit rear ends you? A 27 ton hydraulic ram will pierce a Prius’ hood like a battle axe hitting a whiffle ball and who needs that noise?

Also, trailer lights are super duper cheap and they make your wood splitter look awesome! You can bring your wood splitter to a fancy dinner and say “Hey Jeeves McGotrocks, does your woodsplitter have trailer lights? Oh, really it doesn’t? Well mine does and I just drive around with it all day flashing the brake lights to show it off.” OK maybe not… point is that trailer lights do stand out when you’re hauling in the dark.

I found this Trailer Light Kit on Amazon (for $22.25) but if you buy it you’ve paid too much. Like five bolt trailer wheels and tires, you can get trailer lights so cheap it’s almost unreal. I think I paid under $5 each for two lights (maybe less) and that includes a bulb. I have no idea how they can even think of making a profit for something like that shipped from China. Also, life is hard for a wood splitter. I fully expect to smash a lamp with a chunk of wood sooner or later. If it’s $5 a lens, who cares. I plan on buying a few spares and just stashing them in my tool box.

I have the only wood splitter with trailer lights in the county. Folks think I’m uppity but I still remember growing up in a dirt shack.

. . .

So what’s all this mean? It means that I spent about $50 more than I’d have paid for cheap parts from Northern Tool and I got the perfect axle. I probably saved a bit on welding because the welder guy didn’t have to dink around cutting axle metal to length or lining stuff up. (And I didn’t have to pack the bearings… which is no big deal but I don’t like doing it.) For an extra $50 you cant go wrong.

Tires and trailer lights are proof that China wants everything to be free. Also that Troy Bilt can kiss my ass when they quote prices on their parts.

I’m almost done… but this post has gone on far too long.

A.C.

P.S. In the interest of full disclosure, if you click on the Amazon links and buy anything, regardless of what it is, I get a few bucks to waste on beer. And for that I salute you! But I also posted so you know the components to look for and those are about what you’d need. Most of this stuff came off a boat from China and so you’re looking for fit first, price second, and quality is pretty much the same all around. Aside from tires and lights I couldn’t find Jack shit locally so Amazon (with Prime Shipping) would have been about average pricing for me. (It’s only through luck and diligent searching I found a guy who could order me an assembled whole.)

Great write up. But… wheres the link to the axle you actually bought? Or did i have too many beers?

I ordered the custom axle at a local place that (to my amazement) frequently orders custom axles for its clients. Lots of folks make or improvise utility trailers, ice shacks, and/or retrofit shot boat trailers and this was the “go to” guy.

I was the first loon to show up with a wood splitter but it was just a matter of checking the boxes for “really small” axles instead of the usual sizes. I filled out the form with the proprietor as we took all sorts of complex measurements. It wasn’t unlike a mechanic’s vision of a Chinese menu. He waited until several other orders piled up and FAXed the group off to be made in a magic axle shop several hundred miles away. Then I waited several weeks while it was made. Then I waited a few more weeks before the proprietor decided he had a suitable truckload of axles waiting to be picked up. Patience on the part of axle customers meant free shipping!

So it’s not something to which I could link. It’s a local thing. That said, there is most certainly a guy who does the same thing in your general vicinity; if you can find him. And yes, my axle was welded up in the U.S. of A. and not in a Chinese factory.

It’s not too late to put mag wheels on it.

How about a picture or two of the finished product? Show off your engineering prowess!

Trapped in the city’s find your firewood saga fascinating.

–Ed

I’ll post photos when I get around to it. Weather is too nice right now.

Well done! You apparently did your research and put together a complete, well thought out package.

Please post pictures of the completed project.

And here I figured you were the kinda guy who would weld his own axle….which is why I suggested the stubs (BTW, you can order the stubs the same way you can order the whole axle…by weight, by starting angle,by direction of turn) The Northern Tools reference was just a handy reference. Any decent trailer place can order axles or stubs.

This post is going in my ‘save’ file, as I have the the exact same splitter. However, my high speed travels with it thus far are when the tractor hits 3rd gear.

You’ve got a great wood splitter. I’m sure I’ll come up with other cool “upgrades” in due time. When I do they’ll work for your machine without the redneck R&D effort. 🙂

But the “redneck R&D effort” is why his neighbors love having him around!

Nothing like “Hey, y’all, watch this!” to bring all the neighbors out of their homes with cold brews in hand…

}:-]

So the real question that is unanswered here is, how many crappy troy built tires could you have bought for what you paid for the new axle, hubs, wheels/tires etc?

I’ll exempt lights.

If its under 3, then I commend you sir on a job well done!

But curse you! you now have me looking at torsion axles as an upgrade for my teardrop…

If the existing spindle would easily accept new hubs so I could swap to the cheap Chinese 5 lug wheel/tire sets (which you can buy for so cheap it’s almost free) then the axle might have been a bit silly. In that scenario the number would be more than 3. But that option didn’t fly. Since the spindle was odd sized and Troy Bilt tried to ream me big time for the wheel, my “solution” became relatively less crazy.

I estimate I ordered the torsion axle (hubs included), paid for welding, replaced the fender, added lights, and upgraded to 5 lug wheels with new bigger high-speed tires for a little over twice what I’d have paid for the insane OEM replacement pricing (I checked at two separate stores because the first estimate seemed so stupid.) I figure the number is less than 3 but only a little less. Call it 2.5 to spare my dignity.

On the other hand if I’d stuck with shitty peanut tires I’d have the same problem again sooner or later. Now it’s amazingly easy to tow and that means I have more flexibility for firewood scrounging. For example; I can tow it to work and pick up some firewood after work. Or I can grab just a handful of wood whenever I want. In the old days I only limped the splitter to a new “jobsite” if there was “enough” wood to merit the slow sketchy drive. Now I can tow it for a half load if either the supply is small or time is short. Nor do I have to leave the splitter abandoned under a tarp somewhere if the supply is bigger than I can gather in one visit. It’s also nice to always come home with fully “processed” wood.

I’ll grant you, it wasn’t the cheapest solution but it sure is nice to have good tools.

. . . . .

Ironically, much of my “free” supply came from a storm a few years back. Myself and other wood scroungers have gradually cleaned up a lot of the mess so my “free supply” has dwindled a bit. I may have to harvest on my own land until the next big windthrow event. (That’s ok, mother nature will get in a snit sooner or later and I’ve got enough in my backyard to coast a few years.)