The following Monday I showed up at the tire store, checkbook in hand. “OK, what’s the damage boss?”

“Can’t fix it.”

“Umm… why?”

“Don’t have the part.”

“So? Order it?”

The guy looked as if I’d just mentioned a totally ‘outside the box’ idea. Then smiled…. brilliant! Ten minutes later he returned with a grim look on his face. “I’ve got the part numbers, you aren’t going to like it.”

I clutched the printout. The price was… well all I can say is TroyBilt can kiss my ass.

“This seems high.”

“No shit, those guys are pretty ruthless.”

“How about some other brand? Like maybe any other brand. It’s just a tire.”

The disappeared and came back quite some time later. “Gee, that thing is a bitch to source.” He showed me some pricing options. He wasn’t happy with them. I could tell he’d tried but some stuff just cost more than it ‘ought.

It turns out that the specific spindle size leads to a specific hub size and this spindle was the precise size to be ‘neither fish nor fowl’. The Troy-Bilt price was obscene. The alternatives were merely gross.

“All right, you tried. Thanks.” I nodded.

And with that we tossed the splitter on my waiting trailer. I handed him a ten, which he pocketed with both eagerness and guilt; like I’d handed him six joints, a smoking gun, and a krugerrand. I rolled out.

The place I bought the splitter is not my favorite place. When I got it I made the conscious decision that buying locally would give me a connection to future service people. Like maybe if I was too lazy to do an oil change or something. Later I decided I’d rather talk to a fencepost.

However they were the nearest official Troy-Bilt dealer. Oddly the parts price was a bit higher and… and the labor to install it was astronomical. “Two hours to mount a tire?” I glowered.

“Well, uh…”

“Do people pay that?”

“Sometimes.” He responded meekly.

Even so I was desperate. I like my equipment to be in top notch shape. Maybe I’d bite the bullet.

“So, you’ve got it in stock?”

“No.”

“So, when can it be done?”

He glanced at a calendar and named a date six weeks in the future. I smiled, thanked him, and left with the splitter still perched on my trailer.

At home I engaged on an epic internet search and found a zillion potential options, of which, very few would fit the spindle. None were particularly inexpensive. I had to face facts, this was going to cost something on the order of a couple hundred dollars. Shit!

(I know what you’re thinking. You saw shitty little tires and wheels like that at Northern Tool for a pittance so you figure I ‘ought to be able to solve the issue for $50 and an afternoon tinkering. I thought that too. But it just didn’t work out. The limiting factor seemed to be an odd spindle diameter. There were options but none were great.)

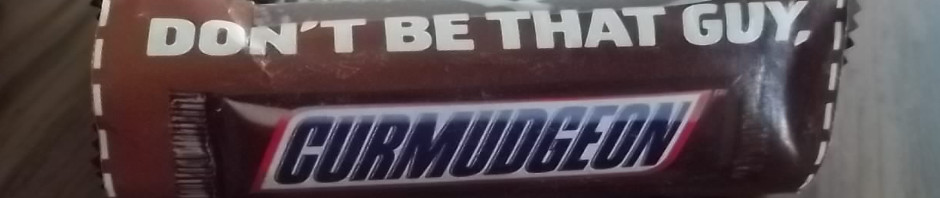

After a few days of moping I’d made my decision. Time for a Curmudgeonly Gem of Insight:

“When it’s already broken and the OEM fix isn’t cheap or easy… bold solutions are more likely to be wise. So quit pussyfooting around and do it.”

Never give up.

A.C.

P.S. I should point out that I’m cheap. I’m sure 50% of the population would have cut the check to Troy-Bilt and pretended like it really takes two hours to mount a mini-tire and been done with it. Being cheap in 2015 is simply odd or at the very least non-conformist. Also I don’t fault Troy-Bilt for raking in some cash from the small base of people who already own and like their device and also beat the hell out of it. All’s fair in economics.

Right now, Harbor Freight has a small trailer on sale for $229. It will hold just over 1000 pounds. Then mount your splitter to the small dedicated trailer. Oh, and this trailer has leaf-spring suapension and real wheels that use four lug bolts!

“I should point out that I’m cheap. I’m sure 50% of the population would have cut the check to Troy-Bilt and pretended like it really takes two hours to mount a mini-tire and been done with it. Being cheap in 2015 is simply odd or at the very least non-conformist.”

I get this a lot when I tell people I am building a tear drop camper.

“Why would you do all that work, why not just BUY one?!?”

Um, cause someone has to do that work, and my work is relatively free when it goes to something fun like this. Besides even if I build it with the most top notch components, with top notch tools, its still going to cost me less than the cheapest meanest commercial built tear drop out there.

Besides there’s the satisfaction of accomplishing something that many people will never know. Each little step along the way (hey the frame is bolted together and the axle is mounted) can be enough to the keep you going for the next little endorphin high.

Besides, if you’d just done that the story would be over, and wheres the fun in that? Being cheap may be easy, but it doesnt make for as good of stories!

Doh, I meant not being cheap…. I fails at the interwebz today

Surely you didn’t decide to strip the Cummins out of your Dodge and repurpose the Ram as a woodsplitter trailer?

}:-]

If I get another bout of “death wobble” I’ll do it!

Harbor Freight may have a trailer available, but (as most things therein) it probably will last not quite as long as the original tire. That being said, I can’t be the only one that is hoping this story ends with the woodsplitter being attached with firm bolts to a solid front axle from a wrecked half-ton pickup, with full size tires in a standard size. It’d probably be easier to roll, too.

With the cat firmly attached to the tongue as a “hood ornament”…

}:-]

Bingo. My first thought. Or even a used trailer axle, complete with standard tires would like be cheaper, better too.

Try Redneck. They sell every conceivable part and accessory for trailers, including complete axles.

http://www.redneck-trailer.com/Portals/4/web_content/files/A.pdf

Or wade through here:

http://www.easternmarine.com/

Yeah, trailer house axle, maybe.

Or….cut a slice off one of those oak cookies of appropriate size, drill a hole in the center, apply a lot of grease, a big washer and cotter pin! It will probably last as long as those “rim protectors” the splitter came with and besides…you said you were CHEAP!

Two large cookies transfixed on a bundle of recycled rebar firmly wired onto the splitter, with a couple of layers of tyre rubber spiked around them. Runflat! Bargain!

Remove the stub axles, grind back flat, weld in steel rod of correct diameter for new wheels across rear extending correct distance to either side . Figure 120 bucks for wheels and rod.

Or if cheapskate like myself, find brass pipe with same ID as shafts now there and OD to match standard wheel hubs, apply grease, assemble. Might have to thread the stub ends to accept locknuts or drill. washer/cotter – problem solved.

But at least you aren’t THIS guy:

http://www.nbcphiladelphia.com/news/local/Philadelphia-Officer-Driving-Police-Cruiser-Charged-With-DUI-297887491.html

Three flat tires and bent rims…

Craigslist, sawzall, welder, old trailer equals new axle on the splitter.

I’d be replacing the axle as well. Chevy parts are cheap, look for the rear end off one their ’90s minivans….